Building the Batteries of Our Future

Why Graphene?

- Reduced risk of fire or explosion

- Does not produce harmful fumes when charging

- Long lifespan

- Quick charge

- Graphene provides a safer, more reliable option than lead acid and other types of batteries

- The Graphene Cell outperforms other batteries in terms of efficiency, safety, and speed of charge/discharge

Graphene Product Overview

![]()

UNIQUE

Our Graphene Products are safer, more environmentally-friendly, and more efficient than other power solutions

![]()

FIRST TO MARKET

First Graphene solution of its scale available for residential and

commercial use

![]()

TESTED

Our Graphene Energy Cell has

undergone extensive testing

for quality and safety

![]()

AUTHENTIC

Designed with the help and input of experts in the green technology

and power industries

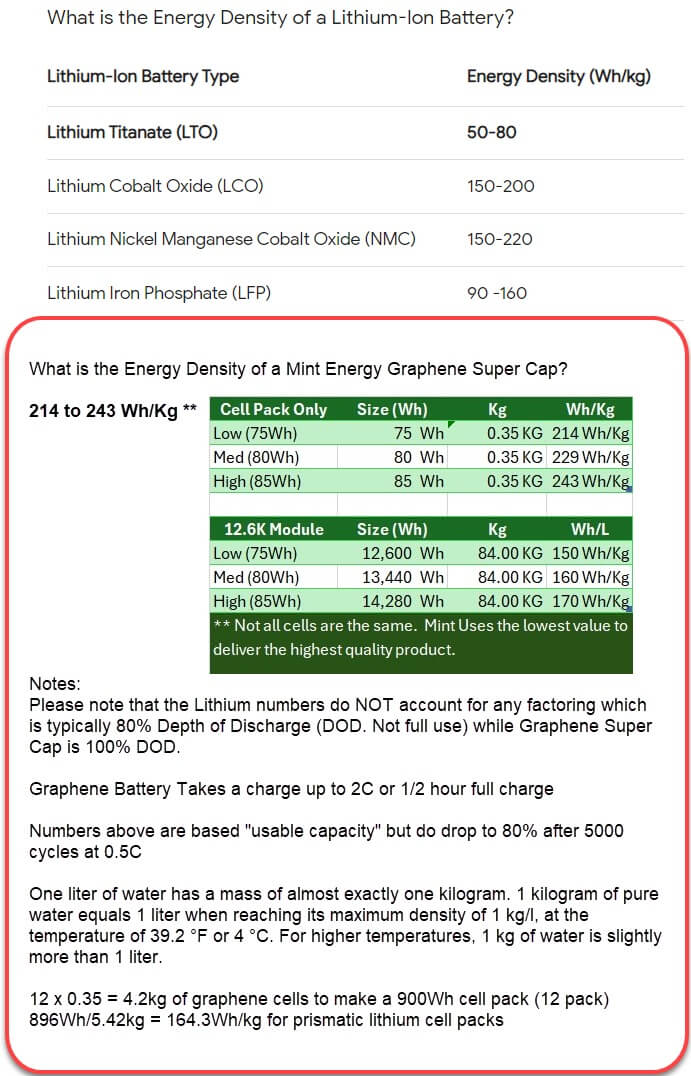

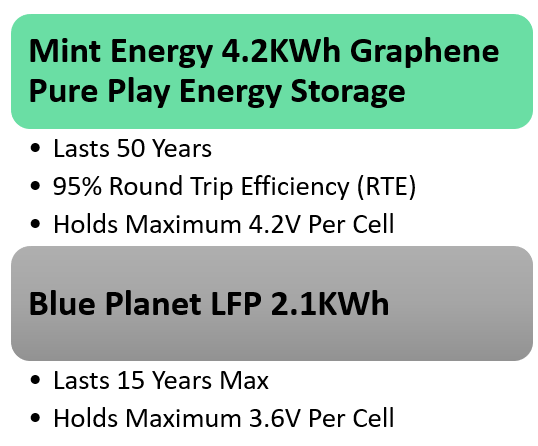

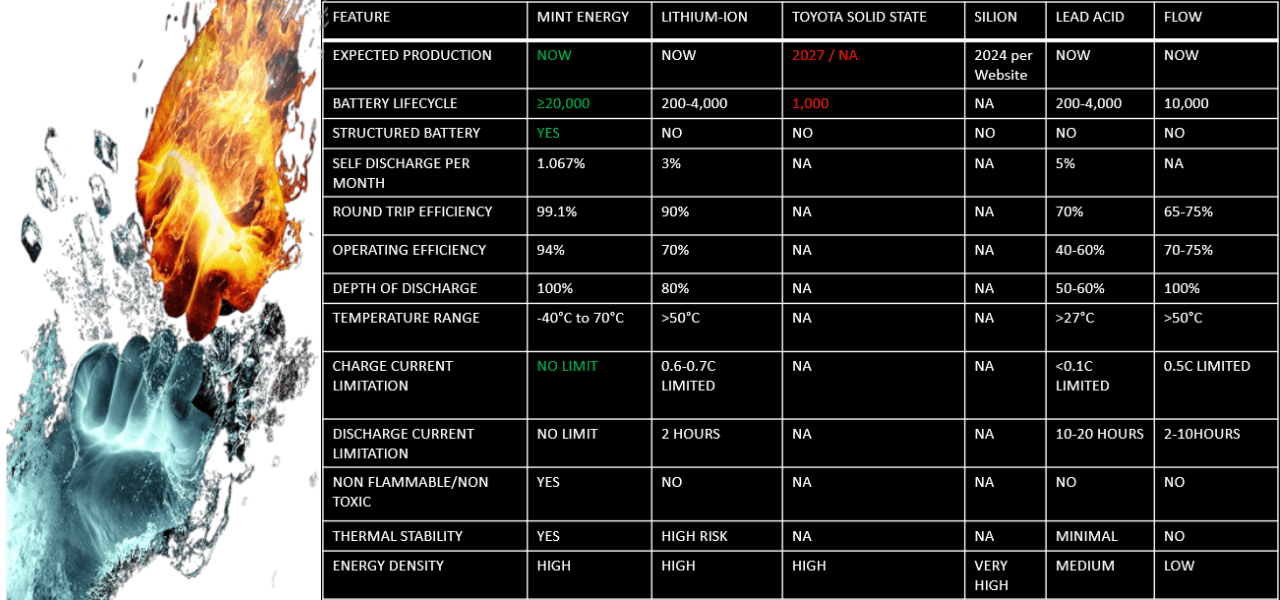

Graphene VS. Lithium-Ion

Superior Product

WE HAVE WHAT EVERYONE WANTS

-

We store MORE POWER – At least 40 times more when you consider voltage

-

Our 4.2 Volts 75Wh Energy Cell can be put into any series and parallel configuration

-

Tank Battery 4(S) + 8(P) = 32 Energy Cells (see Merlin Test) for cold weather lead acid replacement

Cell Design

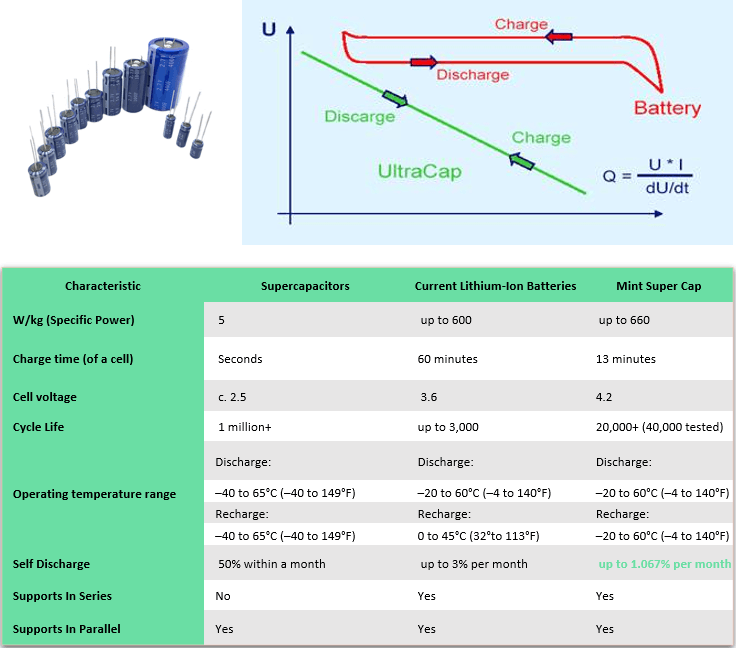

Initial Specifications Single Energy Cell:

- Nominal Voltage 3.7 V

- Max Surge Voltage 4.25 V

- Max Continuos Voltage 4.20 V

- Min Voltage 3.20 V

- Nominal Current 20.00 A

- Continuous Current 40.00 A

Product Testing

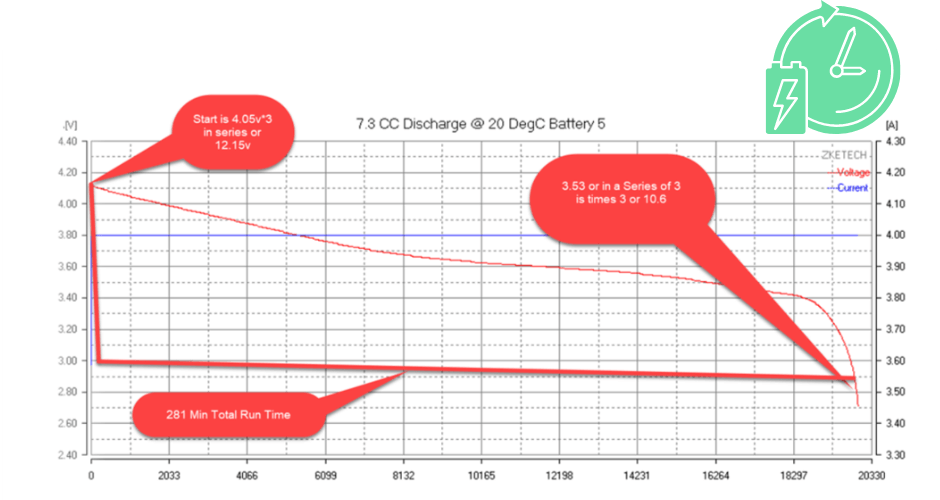

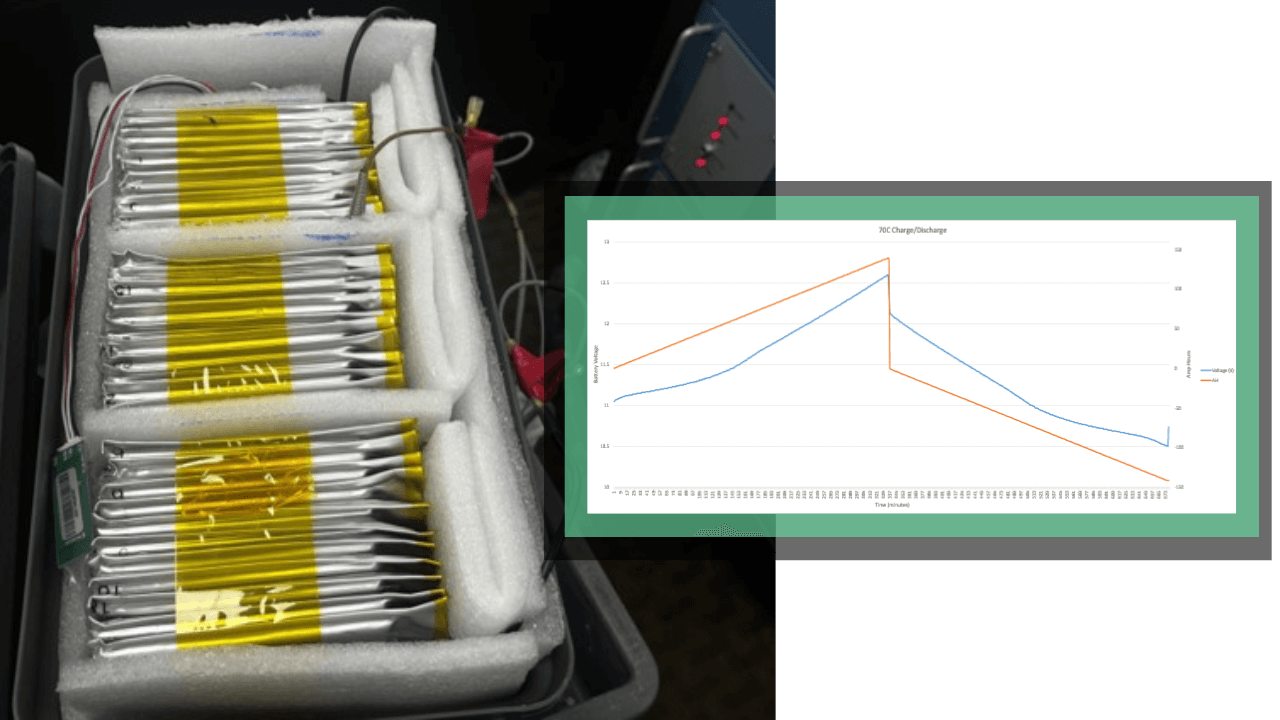

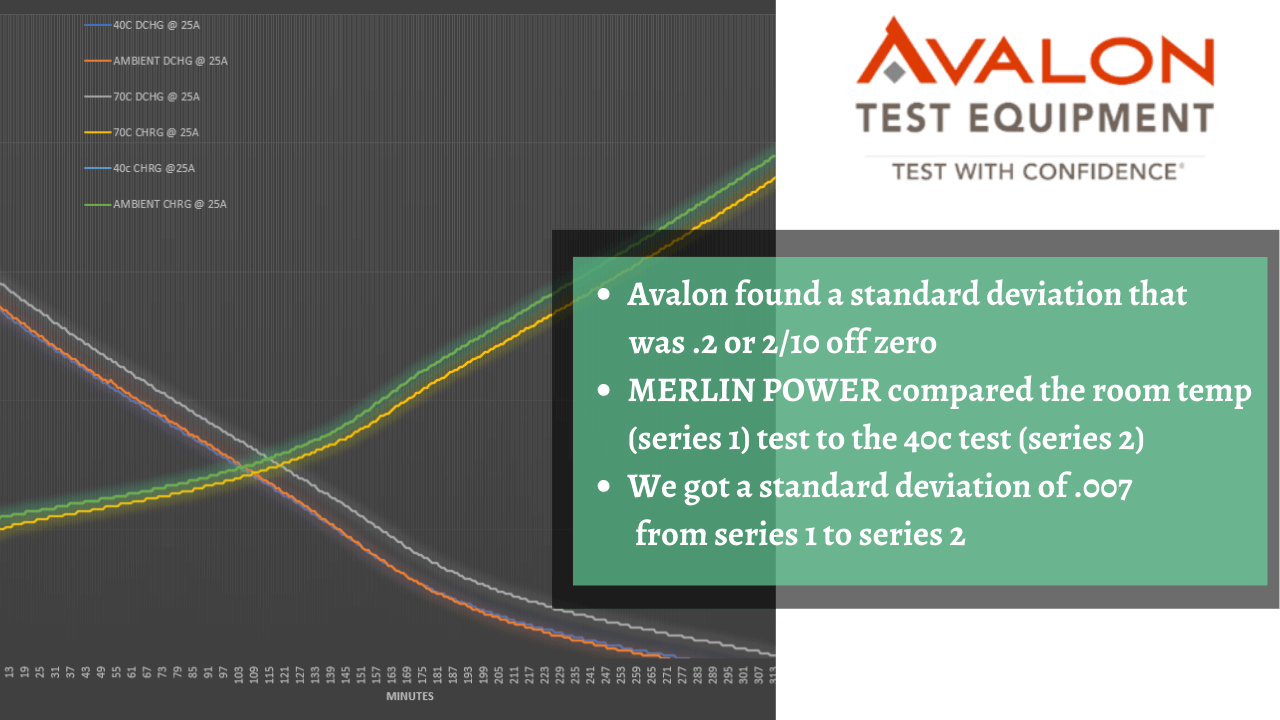

Test Conditions:

Fifteen batteries were arranged in a custom fixture inside a temperature chamber to maintain consistency while maintaining an ambient temperature of 40° C batteries were tested over 5 cycles. The test ran for 96 hours including a 16-hour stabilization period in the test environment.

Test Results:

15 batteries 40°C , at 4A with an average capacity of 21.45 and a SD of 0.2326

Double KWh In The Same Space

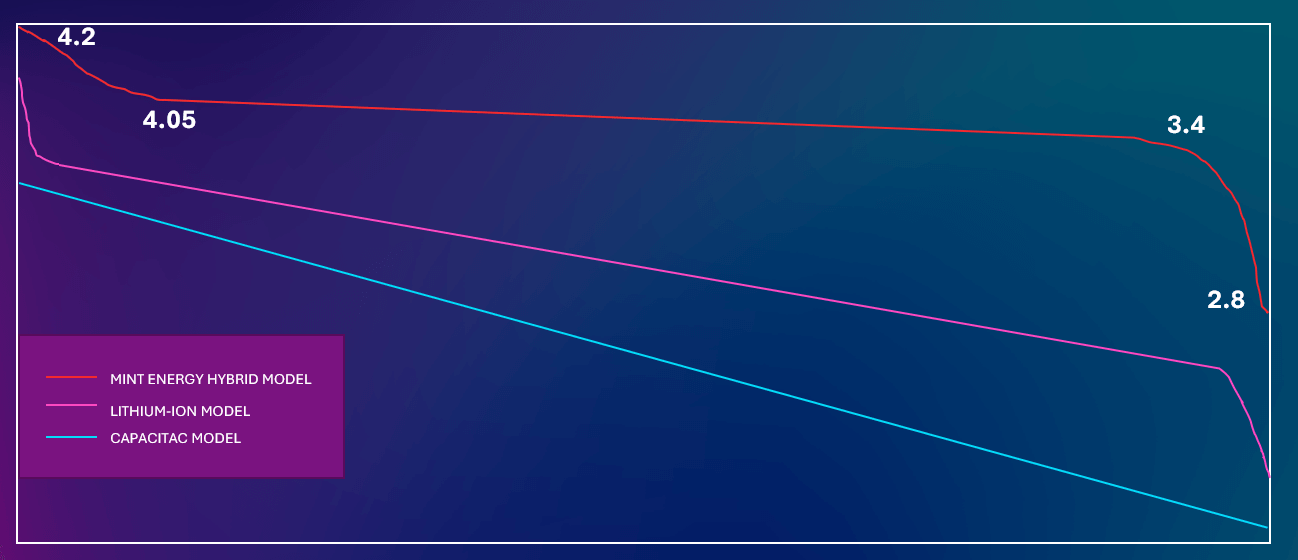

Super Cap That Has A Battery Curve

- Hybrid solution

- Works like a super cap

- Behavior like a battery – low bleed rate

- Safer than other types of batteries

- Long lifespan up to 50-100 years

- Fast charge from zero to 13 min at high 120 amps

- Large temperature ranges supported

- Supports series connections

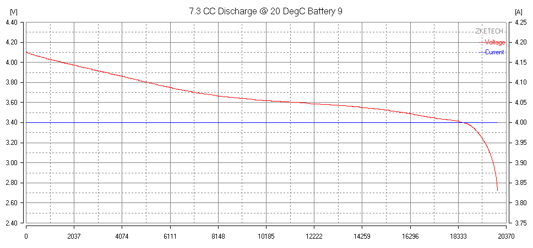

Discharge

Merlin Power Test

Lab Test

Merlin Power Test

Lab Test

Our Competition

Safety Test

Short Circuit Test

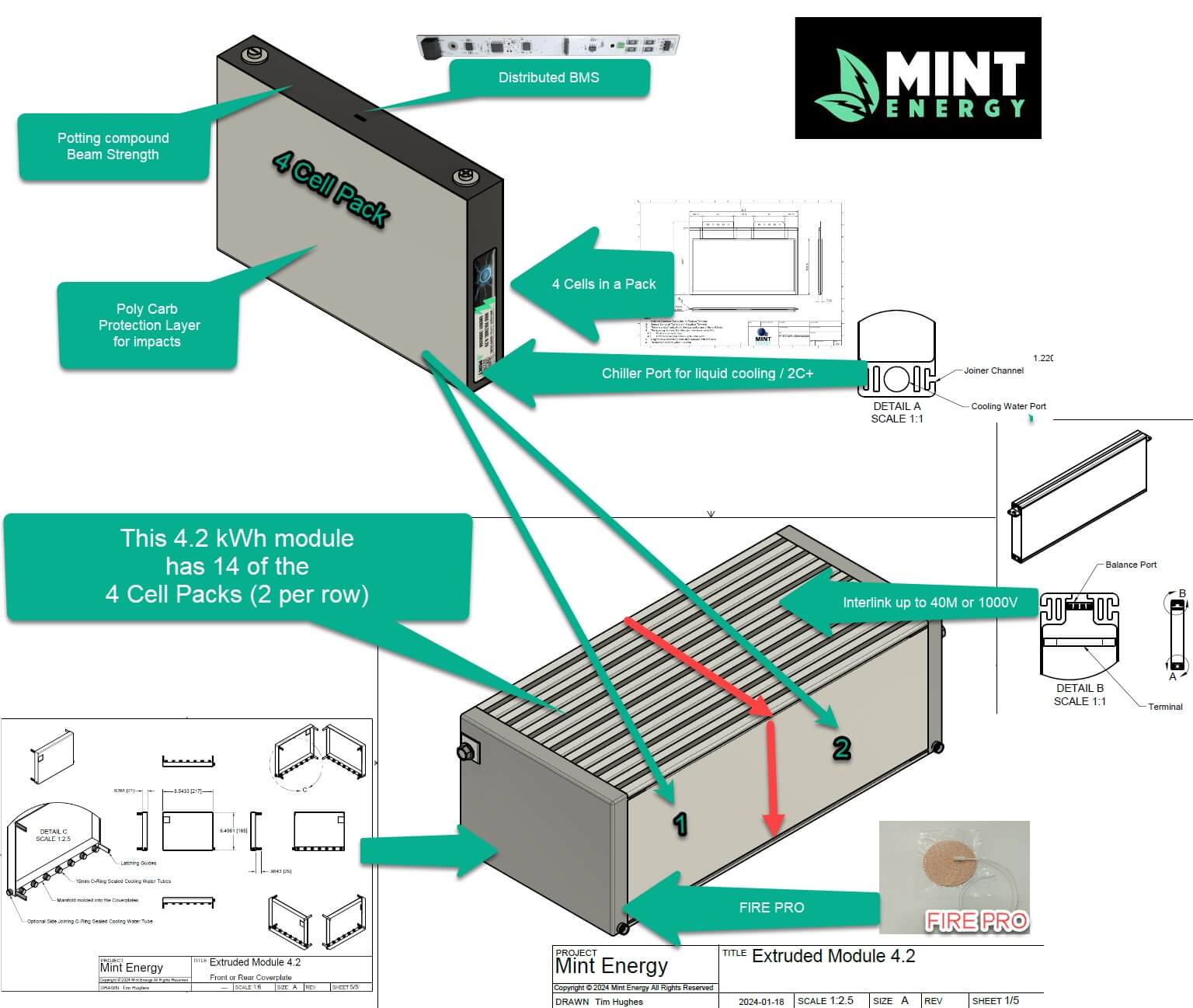

Mint Energy’s Innovative Extruded Model

Mint Energy’s new extruded model is poised to transform battery pack manufacturing. With an extrusion rate of one every 5 seconds, this cutting-edge technology enables the seamless production of battery packs without the need for traditional metal components or welding. By utilizing the battery itself as the busbar, Mint Energy eliminates complexity and enhances efficiency in the production process.

This innovative approach allows Mint Energy to produce battery packs of impressive dimensions, reaching up to 40 meters or 120 feet in length. The flexibility to customize pack sizes to meet specific project requirements is further enhanced by the ability to physically cut down packs to size post-production.

Beyond revolutionizing battery pack manufacturing, the extruded model opens doors to diverse applications. Mint Energy envisions utilizing these battery packs as pillars to support the track of pod systems, including the TransitX system, offering sustainable and scalable solutions for modern transportation infrastructure.

Transitioning to the new extruded model also brings significant advancements in battery management. With one Battery Management System (BMS) per 5 MWh, Mint Energy achieves unparalleled product quality and performance. This streamlined approach ensures optimal efficiency and reliability across large-scale energy storage solutions, delivering superior outcomes for clients and the environment alike.

Mint Energy’s new extruded model marks a pivotal step forward in battery technology.

- Increased Efficiency: Extrusion allows for faster production rates, with the ability to create battery components rapidly, leading to higher throughput and reduced manufacturing time.

- Cost Savings: By eliminating the need for metal and welding processes, extrusion reduces material and labor costs associated with traditional manufacturing methods, resulting in overall cost savings.

- Enhanced Durability: Extruded battery components tend to have superior structural integrity and durability compared to welded counterparts, reducing the likelihood of failures or defects during operation.

- Flexibility in Design: Extrusion enables the creation of complex shapes and profiles, offering greater design flexibility to accommodate specific performance requirements and space constraints in battery pack designs.

- Scalability: The extrusion process can be easily scaled up to meet increasing demand, allowing for efficient mass production of battery packs without sacrificing quality or consistency.

- Integration with Other Systems: Extruded battery components can be seamlessly integrated into larger systems, such as pod transportation systems like TransitX, offering versatility and compatibility across various applications.

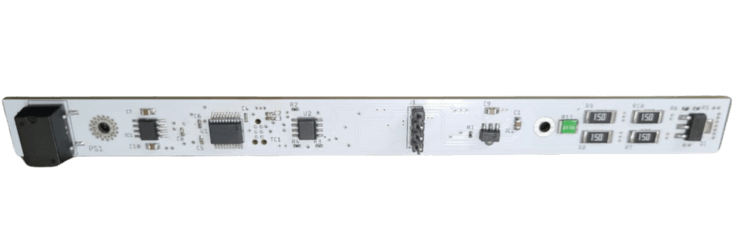

Mint Energy’s Battery Management System (BMS)

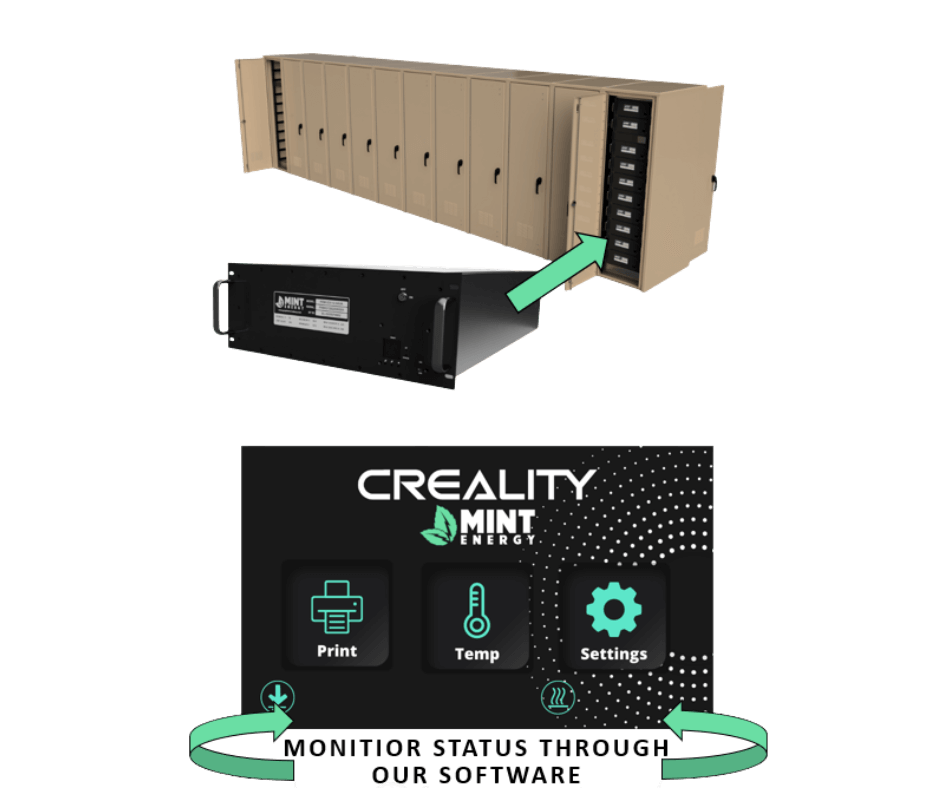

Graphene Container

- Silent Operation

- Safety Features Installed

- Smart Features Monitor Status

- Up To 12 MWh Capacity

- Meets The Power Needs Of 1,400 homes

- Integrates With Any Source Of Power

- Fast Charge/Discharge

- Long Lasting Solution

- Supplies Power To Remote Areas

- Drop In Solution

- Cost-Effective

- “Touch and Go” Power

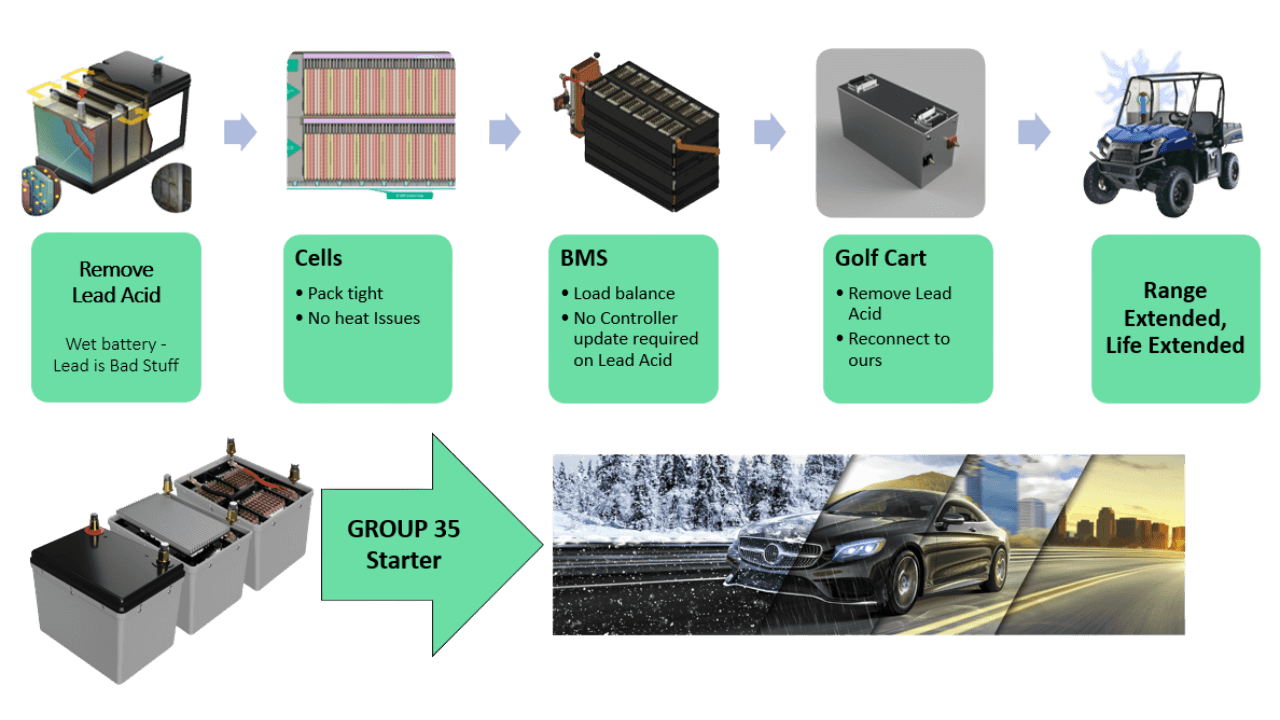

Extend the Life of Vehicles

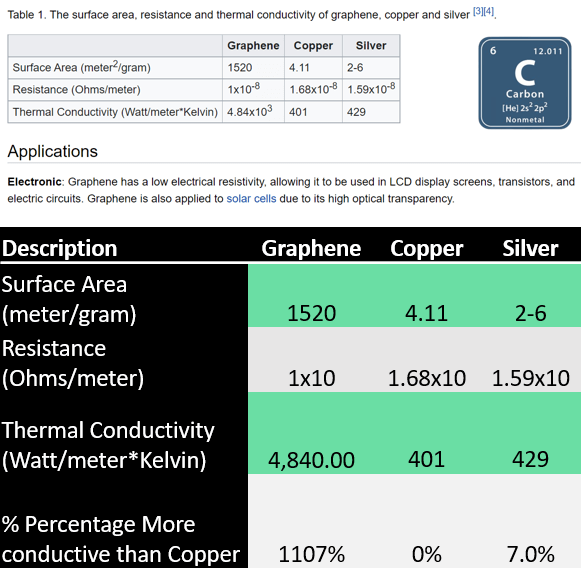

Smaller Mass

- Atomic weight impacts the transfer of power

- Larger / heavier = slower transfer of power

- The atomic weight of copper is 59.6

- The atomic weight of lithium iron phosphate is 155

- The atomic weight of graphene is 12.1

- Metals, including copper, contain elements or neutrons that cause resistance

- There’s resistance in lithium iron phosphate batteries as well

- Our Battery transfers at Thermal Conductivity (Watt/meter*Kelvin) 1107% better than copper

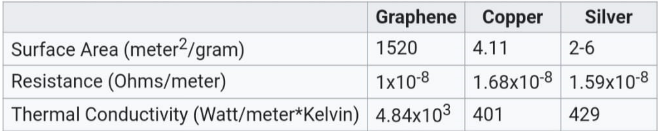

Properties

The electrical and thermal conductivities of graphene are among the highest of any known element at room temperature. The thermal conductivity is the rate in which thermal energy can transfer across a material. The surface area is the total area of the objects faces. The electrical resistance of graphene is among the lowest of any known material at room temperature. It can be defined as the ease in which electrons can pass through the material. Graphene also has very high transparency to light, only absorbing 2.3% of the total white light passing through it. Currently, graphene is very expensive, but its price is predicted to drop by a factor of 4 by the year 2022.

The surface area, resistance and thermal conductivity of graphene, copper and silver

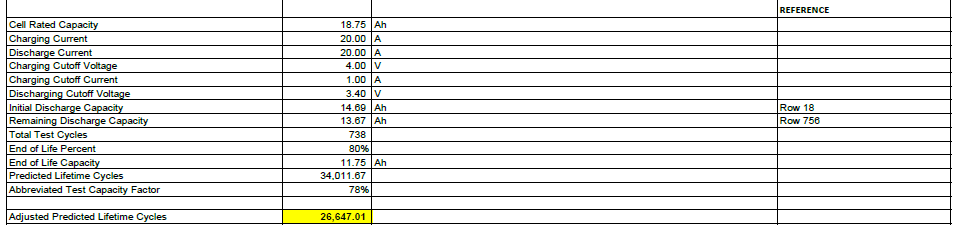

Predicted Lifespan

Notes:

1. Initial Discharge Capacity was pulled from Row 18 of the Commented Extended Cycle Testing completed on 2023-03-21

2. Remaining Discharge Capacity was pulled from Row 756 of the Commented Extended Cycle Testing completed on 2023-03-21

3. Row 18 and Row 756 are the highest discharge capacities from near the beginning and end of the test data

4. Total Test Cycles (738) is the total number of cycles captured between those rows

5. The Predicted Lifetime Cycles is then calculated to the formula detailed below

6. The Abbreviated Test Capacity Factor is calculated as the percentage of Initial Discharge Capacity vs the Cell Rated Capacity

i.) This represents the percentage of capacity that each cycle is charging/discharging and thus represents the effective stress imposed on the cell

7. The Adjusted Predicted Lifetime Cycles represents the lifetime if we were actually testing to 100% DOD

N = adjusted Predicted Lifetime Cycles which is calculated using the following formula:

Where:

C0 is the initial discharge capacity;

Cn is the remaining discharge capacity after cycle test;

n is the completed cycle number;

I is the constant discharge current in the cycle test, 1=20 A.

This formula is recognized and accepted by the China CEPREI Laboratory/China Electronic Product Reliability and Environmental Testing Research Institute and IEC 61960:2011 standards as a valid method of predicting battery lifespan. IEC 61960:2011 is an International Standard which specifies performance tests, designations, markings, dimensions and other requirements for secondary lithium single cells and batteries for portable applications. The objective of this standard is to provide the purchasers and users of secondary lithium cells and batteries with a set of criteria with which they can judge the performance of secondary lithium cells and batteries offered by various manufacturers. This standard defines a minimum required level of performance and a standardized methodology.

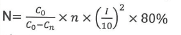

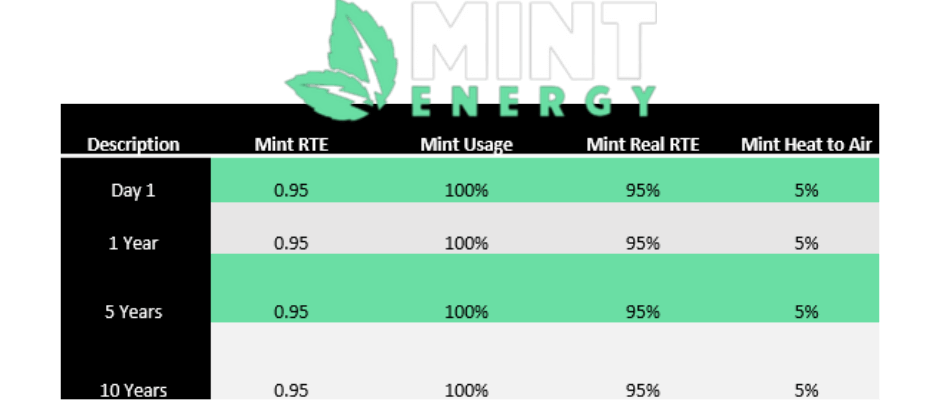

Round Trip Efficiency

- Round-trip efficiency is the percentage of electricity put into storage that is later retrieved – The higher the round-trip efficiency, the less energy is lost in the storage process

- It’s your indirect cost to run a storage system of energy

- The heat burn-off energy or the amount of power you have to put in a transmission line to get it to the destination is around 150% of what is used

- Why is it important?

- It shows you the “REAL” costs of a system

- Lithium-ion batteries are particularly efficient (about 95% on average) while lead-acid batteries tend to fall in the 75-80% range

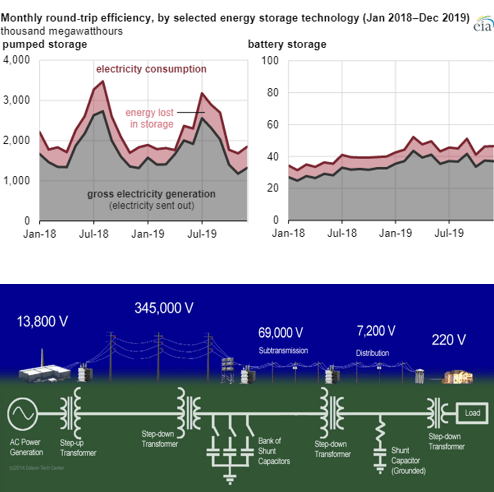

How efficient are transmission lines?

- The transmission over long distances creates power losses

- Most of this energy loss comes from the Joule effect in transformers and power lines – The energy is lost as heat in the conductors

- The overall losses between the power plant and consumers are range from around 8% to 15%

- This equates to 92% to 85% efficient

- You still must pay 100% of the direct costs plus the 8% to 15% indirect cost in EVERY transmission or use

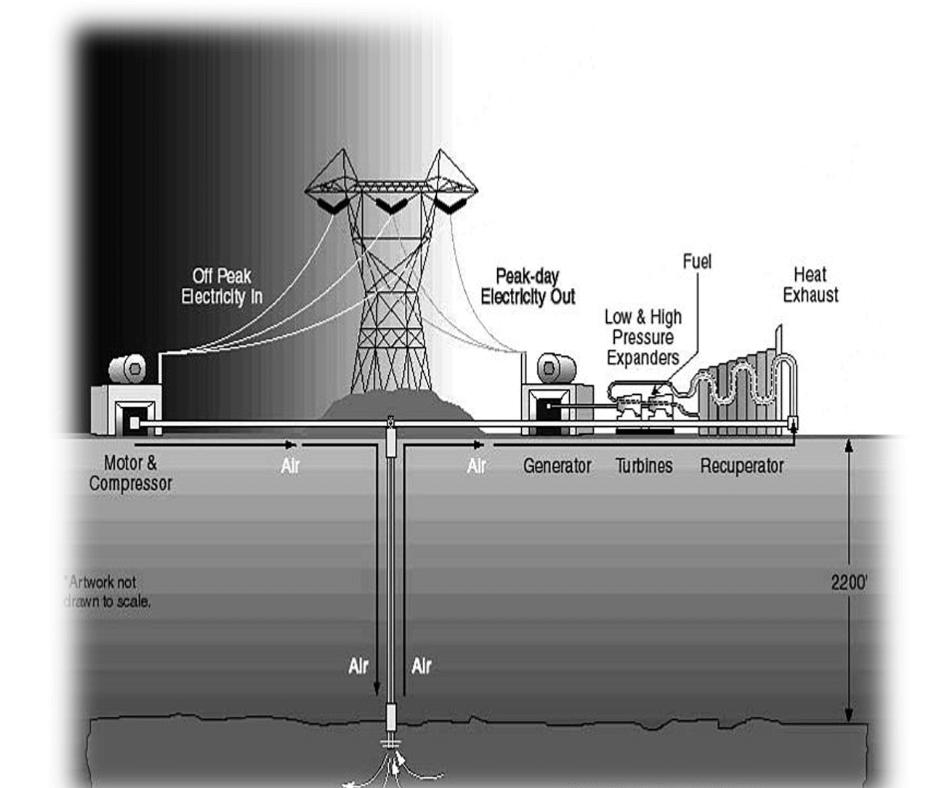

Example – RTE Compression of Gas

- Compression of gas using a Compressor and Diesel Generator

- Only one reason = Peak vs. Off-Peak, otherwise you put it into the grid

- Mechanical System that needs a power source to run the generator and then the compressor

- Compressor units of energy based on 19.2 efficiency ratio

- To get 1 unit of storage, you need to use 5 units of energy (5 to 1)

- You need diesel fuel to run the compressor

- To run solar, you would need a battery that would deplete 5 times for every one unit of energy (5 to 1)

- You spend money on making 10 units of energy to create one unit of storage

- This isn’t a viable long-term solution

- 1000% more expensive

- Reference: https://phys.org/news/2010-03-compressed-air-energy-storage-renewable.html

RTE Comparison – Hydrogen

- Considering the industrial production of hydrogen and using the current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–80%

NOT TRUE!

- Producing 1 kg of hydrogen (which has a specific energy of 143 MJ/kg) requires 50–55 kWh (180–200 MJ) of electricity

- You use 143MJ/kg and get out 180-200MJ

- That is 21% efficiency

Why is hydrogen electrolysis inefficient?

-

- The equivalent round trip from electricity into hydrogen by electrolysis and back into electricity through a fuel cell is less efficient

- There are losses in the conversion and elsewhere in the process of getting energy into vehicles

- The equivalent round trip from electricity into hydrogen by electrolysis and back into electricity through a fuel cell is less efficient

REAL HYDROGEN STORAGE NUMBERS

- ACTUAL Hydrogen has an average 15.6 efficiency ratio

- To get 1 unit of storage, you need to use 6 units of energy (6 to 1)

- You would need diesel fuel to run the PEM

- To run solar you would need a battery that would

deplete 5 times for every one unit of energy (5 to 1) - To run Diesel , its 20% to 26% Efficient (4 to 1)

- To run solar you would need a battery that would

- You spend money on making 10 to 11 units of energy to create one unit of storage

- This isn’t a viable long-term solution YOU ARE ROBBING ONE CYCLE TO GET TO THE NEXT ONE

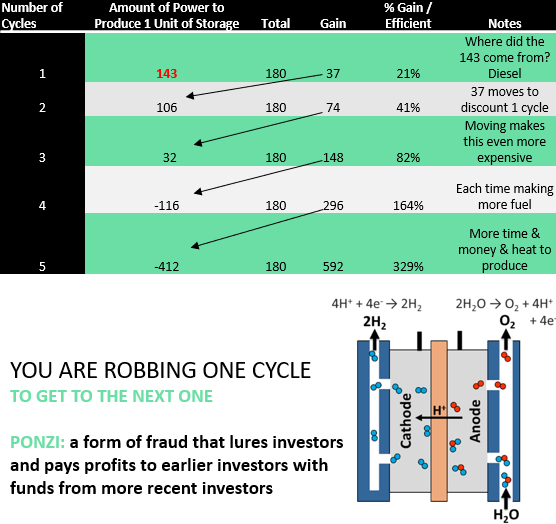

RTE – Lithium

LITHIUM STORAGE:

- Has a heat to air loss on day one of 36%

- This means that you lose 36% of your investment when you turn it on (like a new BMW when you drive it off the car lot)

- On average, you lose 45% of your investment across a 10-year period to heat

- That is basically 0.55 to 1 units of energy, or in this case, 45% is lost on creating 55% or 1 unit of storage (2 to 1)

- You are literally burning money

- While the 10-kilowatt-hour option has been removed, the Powerwall website continues to offer specifications for Tesla’s 6.4-kilowatt-hour battery designed for daily cycling applications including load shifting

- The battery is warrantied for 10 years, or roughly 5,000 cycles

- You must spend 155.00% of energy to get 1 unit of Storage

Mint Energy Graphene Products

MINT ENERGY GRAPHENE BATTERY STORAGE

Has a heat to air on day one of 5% or 2.5% on grid-scale one way to the grid

On average, you lose 5% of your investment across a 50-year period or 20,000-cycle period to heat

95% efficient – To get one full unit you need 105% power

Ready to start your project?

Contact us to start with a demo unit for your needs at sales@mintenergy.com